Thread Plug Gages Instrument Information

Thread plugs play a crucial role in ensuring accurate thread fit for quality control in various industries. Fox Valley Metrology provides ISO/IEC 17025 accredited calibration services for thread plugs, delivering high precision and full NIST traceability for reliable measurements in every application.

Our expert technicians utilize advanced equipment to ensure accuracy across the full range of thread plug types. For in-lab calibration, we are capable of measurements up to 40 inches, while on-site services are performed up to eight inches.

We employ the most thorough processes available to ensure proper fit and the utmost level of tolerance compliance. Both “go” and “no-go” thread plug members are calibrated through our standard thread plug calibration process:

- Multi-Point Inspection: We inspect the front, middle, and back of the “go” side, as well as the front and back of the “no-go” side, confirming accuracy throughout the entire gage length.

- Pitch Diameter Verification: Using the precise 3-wire method, we verify the pitch diameter to ensure threading accuracy.

Fox Valley Metrology’s ISO/IEC 17025 Accredited Thread Plug Gage Calibration Services Include:

- Taperlock Thread Plug Calibration

- Reversible Thread Plug Calibration

- Trilock Thread Plug Calibration

- UN Series Thread Plug Calibration

- Metric Thread Plug Calibration

- BSPT Thread Plug Calibration

- NPT Thread Plug Calibration

- NPTF Thread Plug Calibration

- BSPP Thread Plug Calibration

- ACME Thread Plug Calibration

- Buttress Thread Plug Calibration

- Go Thread Plug Calibration

- No-Go Thread Plug Calibration

With our comprehensive and precise calibration process, you can rely on your thread plug gages for dependable thread accuracy, supporting your quality control needs across all applications.

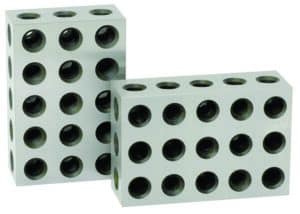

What is a Thread Plug?

A metallic cylinder, containing a handle, machined to a precise diameter and threaded to a precise size. The gage is screwed into the internal thread of a machined part. The gage often comes in a Go/No-Go combination, connected by a handle. Often, the machined part is considered in tolerance if the Go end goes into the threaded hole smoothly and the No-Go end engages, but does not thread over three complete turns.

Common Thread Plug Uses

Verifying that internal threads on machined parts meet specified dimensions and tolerances for proper mating with external threaded parts.

Common Thread Plug Classes

UN Series Thread Plugs:

- UNC – Coarse pitch series

- UNF – Fine pitch series

- UNEF – Extra fine pitch series

- UNJ – Constant pitch series, with rounded root on external threads & thread ring gage

- UNJC – Coarse pitch series, rounded root on external threads & thread ring gage

- UNS – Special diameter, pitch or length of engagement

- UNJF – Fine pitch series, rounded root on external threads & thread ring gage

- UNJEF – Extra fine pitch series, rounded root on external threads & thread ring gage

Metric Thread Plugs:

- M – Basic thread profile as specified in ISO 68

- MJ – MJ profile with round root on external threads and thread ring gage

- MJS – MJ profile special series on external threads and thread ring gage

Thread Plug Calibration Services

Construction Type:

- Taperlock Thread Plug Calibration

- Reversible Thread Plug Calibration

- Trilock Thread Plug Calibration

Thread Designation System:

- UN Series Thread Plug Calibration

- Metric Thread Plug Calibration

- BSPT Thread Plug Calibration

- NPT Thread Plug Calibration

- NPTF Thread Plug Calibration

- BSPP Thread Plug Calibration

- ACME Thread Plug Calibration

- Buttress Thread Plug Calibration

- JIS Thread Plug Calibration

Member:

- Go Thread Plug Calibration

- No-Go Thread Plug Calibration

- Go/No-Go Thread Plug Calibration

Common Thread Plug Brands We Support

- Vermont Gage Thread Plug Calibration

- Glastonbury Southern Gage Thread Plug Calibration

- Gage Assembly Thread Plug Calibration

- S. Gage Thread Plug Calibration

- Thread Check Thread Plug Calibration

- WESTport Thread Plug Calibration

- Swanson Tool Thread Plug Calibration

- Spiralock Thread Plug Calibration

Thread Plug Calibration Standards & Procedures

- ANSI B1.2-1983 (Gages and Gaging for Unified Screw Threads)

- ANSI/ASME B1.16M-1984 (Gages and Gaging for Metric M Screw Threads)