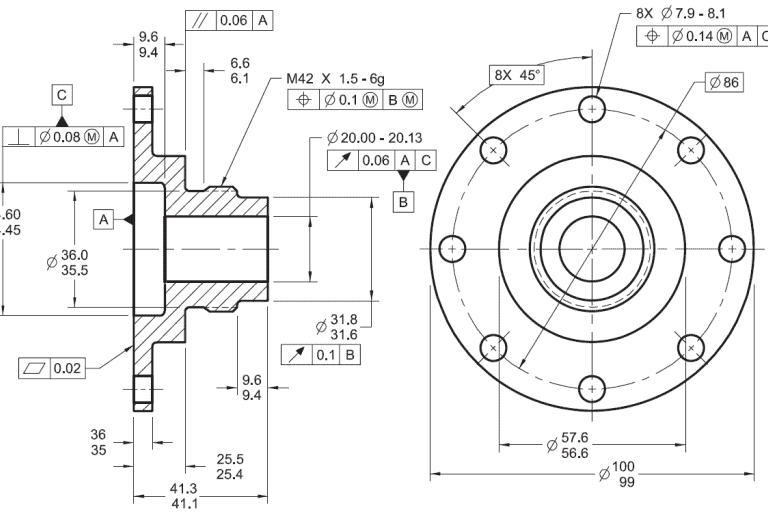

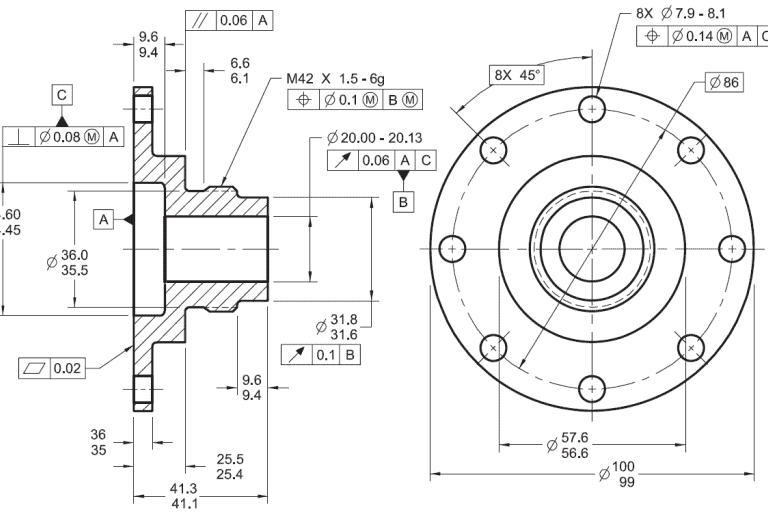

Geometric Dimensioning & Tolerancing (GD&T) – Fundamentals

This GD&T Fundamentals training workshop introduces the student to the basics of the Geometric Dimensioning and Tolerancing of the ASME Y14.5M-2018 standard. It covers terms, definitions, and rules, followed by a close look at the purpose for each of the 14 GD&T symbols.

Geometric Dimensioning & Tolerancing (GD&T) – Fundamentals

This GD&T Fundamentals training is designed for anyone involved in part manufacturing from design through to inspection. It can benefit engineers, technicians, quality personnel, and anyone who has a need to understand, define and/or communicate tolerances on engineering drawings.

Course Objectives

- Gain a comprehensive introduction to the Y14.5M-1994, Y14.5-2009, and Y14.5-2018 standards

- Understand the proper use of Geometric Dimensioning and Tolerancing (GD&T)

- Bridge the gap between designers and measurement personnel

- Learn design and inspection technique to enhance knowledge of inspection methods

- Examine GD&T concepts from both design and inspection perspectives

Target Audience

- Engineers

- Quality Personnel

- Technicians

Agenda

- Unit 1 – Basic Principles and Definitions

- General Dimensioning and Tolerancing Principles

- Coordinate Tolerancing

- Geometric Tolerancing

- Unit 2 – Rules and Advanced Concepts

- Rules and Features of Size

- Bonus Tolerance

- Limits of Size

- Virtual Condition and Boundaries

- Unit 3 – Datums and Datum Reference Frame

- Introduction to the Datum System

- Planar Datums

- Axis and Centerplane Datums

- Datum Shift

- Datum Targets

- Unit 4 – Tolerances of Form

- Introduction to Form Tolerances

- Flatness

- Straightness (Applied to Surface Elements and to Axis or Centerplane)

- Circularity and Cylindricity

- Unit 5 – Tolerances of Orientation

- Introduction to Orientation Tolerances

- Parallelism

- Perpendicularity

- Angularity

- Tangent Plane Modifier

- Unit 6 – Tolerances of Location

- Introduction to Location Tolerances

- Tolerance of Position

- Concentricity

- Symmetry

- Unit 7 – Tolerances of Profile

- Introduction to Profile Tolerances

- Profile of a Surface

- Profile of a line

- Unit 8 – Tolerances of Runout

- Introduction to Runout Tolerances

- Circular Runout and Total Runout

Course Delivery

- In-Person Training

- Online Self-Paced Training

- Training for Teams

- Virtual Live Training

Prerequisites

- Working understanding of technical drawings

- Print Reading for Industry Course